Navigating the Future: How AI is Shaping the Contract Manufacturing Industry in Germany

Where does Germany stand in contract manufacturing?

As we enter the new year, I resolve to consolidate my findings on digitalization and AI in German contract manufacturing. What is our current standing? Who are the real industry leaders? And, importantly, what strategic approaches exist to realize Contract Manufacturing 4.0?

The year 2023 marked a pivotal moment for AI (artificial intelligence). Since the emergence of ChatGPT, AI has gained increasing prominence in industry and business discussions, especially for German manufacturing SMEs. The use of AI is becoming indispensable for Germany’s future as an industrial hub, addressing challenges like a shortage of skilled workers and maintaining competitiveness with low-wage countries, particularly in contract manufacturing.

Regrettably, the digitalization of German contract manufacturing remains stuck in the Stone Age, where a vision of the future collides with harsh reality. For some, digitalization merely translates to “Our sales process is paperless, we communicate via email.”

Family-run companies, spanning the 3rd or even 4th generation, have traditionally navigated market changes and relied on established customer relationships. However, in 2023, this is no longer sufficient. Instead of relying on personal connections, contract manufacturers now face relentless competition through production marketplaces and online manufacturers. The one who can offer comparable quality more quickly at a better price secures the order.

AI is already casting its shadow in contract manufacturing, and what German SMEs discuss and implement reluctantly is already a reality elsewhere. Zetwerk from India leads the way with its B2B Marketplace. Companies upload metal parts they need for prototypes and series production as step files (3D drawings). AI analyzes the model and its production processes, generating a quote at the touch of a button. Delivery time? 3 days.

In summary, the German manufacturing industry, renowned for quality and high precision, stands at a critical juncture. It must answer whether Germany will leverage engineering and industrial know-how, digitalization, and AI to redefine the nature of manufacturing and take on the battle for survival.

Why has there been little adaptation of automated processes and AI so far?

In my view, two main reasons contribute to this

- Missing Industry Solution:

The German contract manufacturing industry grapples with various isolated solutions that no longer meet precision manufacturing requirements. Solutions across different departments, such as design, work preparation, or merchandise management, have grown independently. Despite this, there is a reliance on manual information preparation and processing using Microsoft Excel. To date, scarce end-to-end industry solutions are employing state-of-the-art technologies like cloud computing and artificial intelligence to effectively address current market challenges.

- Resource and Competence Problem:

Severe bottlenecks in IT personnel, expertise, and financial resources hinder actual implementation. In larger companies or corporations, specialized teams with adequate expertise and financial resources often handle the development of concepts and their implementation for digitalization. In contrast, in small and medium-sized companies, this responsibility often lies with individuals within specialist departments who are also heavily involved in day-to-day business.

In 5 Steps to Contract Manufacturing 4.0:

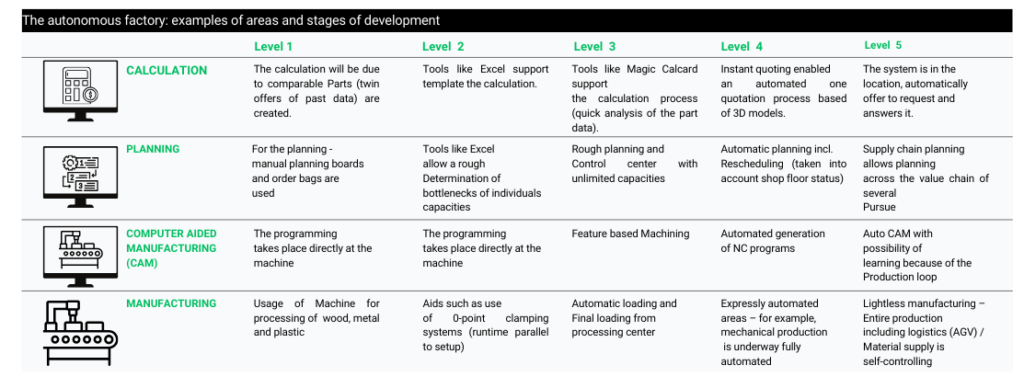

Based on the stage model developed by ISTOS, we aim to propel the contract manufacturing industry in Germany to the next level. The diagram illustrates 5 different levels of automation in the 4 most crucial areas of the contract manufacturing industry. We use these visuals with our clients to derive strategic action areas and determine a gradual development of individual processes toward autonomy. Each contract manufacturer will have a unique mix of integrated and non-integrated systems, with focal points weighted differently to meet specific requirements and achieve individual autonomy.

But what measures can be implemented first, and where are the so-called “quick wins”?

What immediate measures can contract manufacturers take now?

Primarily, we see significant optimization and rapid success opportunities, particularly in administration and sales. According to our latest customer survey, digitized and automated administration, in particular, helps reduce operating costs related to unnecessary administrative steps by up to 20-40%. To take the first step, we recommend the following approach:

Step 1: Actual Analysis of the Processes

To overcome the challenges of digitalization, a thorough inventory is essential. Analyze which processes are characterized by non-integrated systems and identify the operational areas with the greatest need for optimization. Where do the highest costs arise that could be reduced through efficient automation?

Step 2: Evaluation of the Processes

Use a simple 4-field matrix for orientation. This matrix relates the number of non-integrated systems to the pain caused by the current processes, encompassing costs, time expenditure, specialist knowledge, or technological progress in the respective process. Expand the definition of “pain” individually.

Step 3: Deriving a TARGET Model

The ACTUAL model forms the basis for deriving a development plan or TARGET model. Regardless of providers and software, it is crucial that the process and data flow is integrated without manual interfaces. This integration should cover both the horizontal data of production processes and the vertical data of machines and systems. Avoiding manual interruptions is essential. Structured data collection in production at an early stage enables comprehensive evaluations and analyses later on.

CERPRO, Your Production Co-Pilot for End-to-End Process Automation

Cerpro GmbH was founded with the mission to reshape the digital future of contract manufacturing. We are developing an AI-supported assistant for small and medium-sized companies in the manufacturing industry to automate the entire sales and planning process for contract manufacturers.

Together with Demofabrik-Z4, we demonstrate through practical examples how you can drive digital transformation forward. This showcase goes beyond abstract use cases presented with slides, providing a live and close-up demonstration of the impact of robotics, software, and digitalization on the production process.

Contact us for more information, to schedule a demo, or to initiate a conversation about integrating AI technologies into your business.